The type of packaging that companies choose for their products plays many important roles throughout the entire operational supply chain. Packaging is an important factor in marketing products to consumers with appealing aesthetics but is also a critical factor when shipping and storing products and is often one of the largest expenses factored into an item’s production lifecycle.

Making the switch from rigid packaging to flexible packaging can provide significant improvements to a company’s operational efficiencies and bottom line, with the top 5 benefits including:

- Enhanced durability

- Product preservation and extended shelf life

- Optimized shipping space

- Greater product-to-package ratio

- More sustainable packaging and shipping

Flexible Packaging Provides Enhanced Durability

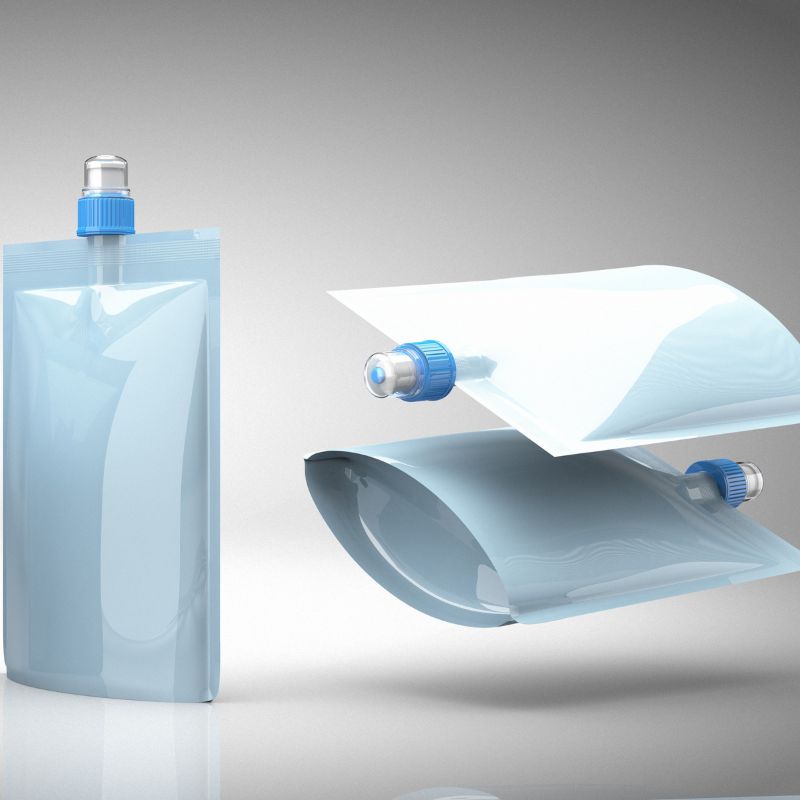

All types of products are damaged every day during shipping which leads to losses of damaged products, a waste of fuel delivering damaged goods, and added costs for reshipping the same products. Packaging materials like corrugated boxes and even dent-prone types of aluminum cans can still experience damage during shipping. Flexible packaging, however, is designed to absorb impact better and is non-breakable. Flexible packaging can be custom designed to incorporate multiple layers depending on the level of protection needed for the product.

Product Preservation and Extended Shelf Life

Flexible packaging materials have the ability to preserve products and extend shelf life. Many types of products benefit from packaging that resists corrosion, oxidation, and moisture, which corrugated and other packaging materials provide limited protection against. Flexible packaging such as stand-up pouches and powder bags has the ability to preserve products with air-tight seals and protective coatings, extending product quality and shelf-life.

Optimized Shipping Space

Stacking boxes on top of skids is the ‘way it’s always been done’ for packaging and shipping a wide variety of products. This often requires dunnage such as air-filled bags, Styrofoam, or wadded-up paper to prevent products from slipping during transit. Filling space with added products costs money and is wasteful in many ways.

Flexible packaging optimizes shipping space with less empty space and no need to pack protection around products in boxes. Flexible packaging can cost much less to ship when rates are based on box dimensions with no need for filler material. This allows for shipping a greater quantity of product on the same truckload, drastically improving logistics and reducing carbon emissions.

Greater Product to Package Ratio

Flexible packaging provides a greater product-to-package ratio, with more product compared to the packaging material used. This means less waste and less resource consumption. A higher product to package ratio also means there is less weight which can reduce shipping costs, and more products can be stored in the same space.

More Sustainable Packaging And Shipping

Flexible packaging is a more sustainable option than other packaging methods, providing sustainability throughout the entire lifecycle, according to the Flexible Packaging Association. Flexible packaging results in less greenhouse gas emission, less fossil fuel usage, less transportation-related energy, and less environmental pollution.

With all of these benefits, companies that make the switch from rigid packaging to flexible packaging can significantly reduce their packaging expenses and improve capacity in their warehouse or facility. Working with an experienced flexible packaging provider helps companies to realize maximum benefits and improvements to their operational efficiencies.

PPS Is a Flexible Packaging Provider

Peoria Production Solutions, PPS, is an experienced contract packaging company offering a wide range of packaging solutions including flexible packaging. We provide secondary packaging solutions to some of the largest corporations in America and improve efficiencies for companies of all sizes. Our skilled staff specializes in wrapping, bagging, filling, and packaging, with high attention to detail and quality-driven policies based on our ISO9001:2015 registration.

PPS excels in meeting our customer needs with high-quality and cost-efficient packaging solutions. We offer packaging, kitting, wrapping, assembly, sewing, and more to act as an extension of your production team. Contact us to learn more about the many benefits flexible packaging can provide to your company when working with an experienced flex packaging provider.